Product introduction

ARCHCELL® UT

ARCHCELL® is a closed-cell rigid PMI (Polymethacrylimide) foam, which used as the core of lightweight sandwich structure.

UT (Ultra-high Temperature) can withstand very demanding process conditions in all ARCHCELL® portfolio, up to 180 °C and 0.45 MPa for conventional grades and even 190 °C and 0.7 MPa after heat treatment. typical curing temperatures for BMI resin systems are up to 210 °C (410 °F) for pressureless post-curing processes. And it is suitable for a variety of curing processes (autoclave, vacuum infusion, RTM, VARTM, VARI, HP-RTM, etc.). It also has good processability and can be easily thermoformed or CNC machined.

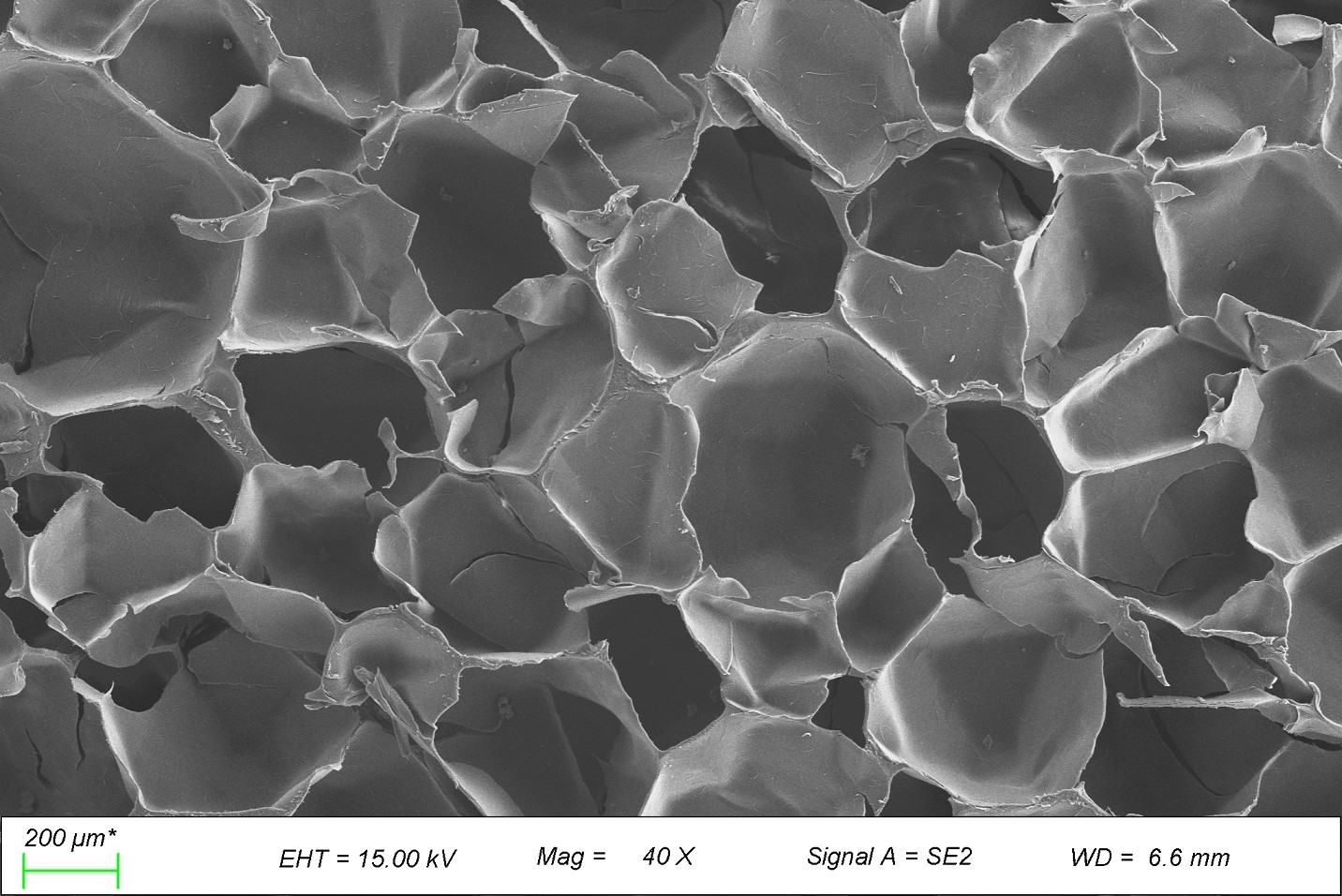

The cell size is an important specification of the foam material and determines the difference in the amount of curing resin absorbed during the foam processing. We have divided it according to the cell size in order to better fit various processes and resin viscosities.

TYPICAL PROPERTY VALUES

ARCHCELL® UT-FC

FC is a fine cell structure that guarantees a lowest curing resin absorption of up to 50g/m2, thus reducing the weight of the final product, and is particularly suitable for vacuum infusion and RTM processes.

|

Properties |

Unit |

71 UT-FC |

110 UT-FC |

Standard |

|

Density |

kg/m3 |

75 |

110 |

ISO 845 |

|

lbs/ft3 |

4.68 |

6.87 |

ASTM D1622 |

|

|

Compressive Strength |

MPa |

1.68 |

3.65 |

ISO 844 |

|

psi |

243.6 |

529.3 |

ASTM D1621 |

|

|

Tensile Strength |

MPa |

2.28 |

3.84 |

ISO 527-2 |

|

psi |

330.6 |

556.8 |

ASTM D638 |

|

|

Shear Strength |

MPa |

1.44 |

2.38 |

DIN 53294 |

|

psi |

208.8 |

345.1 |

ASTM C273 |

|

|

Elastic Modulus |

MPa |

102.9 |

181.1 |

ISO 527-2 |

|

psi |

14920.5 |

26259.5 |

ASTM D638 |

|

|

Shear Modulus |

MPa |

42.2 |

67.9 |

DIN 53294 |

|

psi |

6119.0 |

9845.5 |

ASTM C273 |

|

|

Elongation at Break |

% |

3 |

3 |

ISO 527-2 |

|

ASTM D638 |

||||

|

HDT |

℃ |

239.4 |

243.1 |

DIN 53424 |

|

°F |

436.9 |

469.6 |

The above technical data are typical values at nominal densities

ARCHCELL® UT-MC

MC is a medium cell structure, which can get a good balance between peel strength and light weight requirements.

|

Properties |

Unit |

71 UT-MC |

110 UT-MC |

Standard |

|

Density |

kg/m3 |

75 |

110 |

ISO 845 |

|

lbs/ft3 |

4.68 |

6.87 |

ASTM D1622 |

|

|

Compressive Strength |

MPa |

1.68 |

3.65 |

ISO 844 |

|

psi |

243.6 |

529.3 |

ASTM D1621 |

|

|

Tensile Strength |

MPa |

2.28 |

3.84 |

ISO 527-2 |

|

psi |

330.6 |

556.8 |

ASTM D638 |

|

|

Shear Strength |

MPa |

1.44 |

2.38 |

DIN 53294 |

|

psi |

208.8 |

345.1 |

ASTM C273 |

|

|

Elastic Modulus |

MPa |

102.9 |

181.1 |

ISO 527-2 |

|

psi |

14920.5 |

26259.5 |

ASTM D638 |

|

|

Shear Modulus |

MPa |

42.2 |

67.9 |

DIN 53294 |

|

psi |

6119.0 |

9845.5 |

ASTM C273 |

|

|

Elongation at Break |

% |

3 |

3 |

ISO 527-2 |

|

ASTM D638 |

||||

|

HDT |

℃ |

239.4 |

243.1 |

DIN 53424 |

|

°F |

436.9 |

469.6 |

The above technical data are typical values at nominal densities

ARCHCELL® UT-CC

CC is a coarse cell structure with the highest adhesive absorption and the best peel strength.

|

Unit |

71 UT-CC |

110 UT-CC |

200 UT-CC |

Standard |

|

|

Density |

kg/m3 |

75 |

110 |

205 |

ISO 845 |

|

lbs/ft3 |

4.68 |

6.87 |

13.73 |

ASTM D1622 |

|

|

Compressive Strength |

MPa |

1.68 |

3.65 |

9.01 |

ISO 844 |

|

psi |

243.6 |

529.3 |

1306.5 |

ASTM D1621 |

|

|

Tensile Strength |

MPa |

2.28 |

3.84 |

6.85 |

ISO 527-2 |

|

psi |

330.6 |

556.8 |

993.3 |

ASTM D638 |

|

|

Shear Strength |

MPa |

1.44 |

2.38 |

4.82 |

DIN 53294 |

|

psi |

208.8 |

345.1 |

698.9 |

ASTM C273 |

|

|

Elastic Modulus |

MPa |

102.9 |

181.1 |

350.2 |

ISO 527-2 |

|

psi |

14920.5 |

26259.5 |

5779.0 |

ASTM D638 |

|

|

Shear Modulus |

MPa |

42.2 |

67.9 |

145.4 |

DIN 53294 |

|

psi |

6119.0 |

9845.5 |

21083.0 |

ASTM C273 |

|

|

Elongation at Break |

% |

3 |

3 |

3 |

ISO 527-2 |

|

ASTM D638 |

|||||

|

HDT |

℃ |

239.4 |

243.1 |

241.6 |

DIN 53424 |

|

°F |

436.9 |

469.6 |

466.9 |

The above technical data are typical values at nominal densities

Sales Range

|

Grade |

Size(mm) |

Standard Sheet Thickness(mm) |

Possible Sheet Thickness(mm) |

|

71 HT |

2500*1250 |

80 |

1-140mm |

|

110 HT |

2160*1100 |

70 |

1-115mm |

|

200 HT |

1900*900 |

60 |

1-90mm |

Thickness tolerance±(0.2mm)

English

English

Chinese

Chinese